The Blade has defined the 5-batten wave sail category for 20 years. The latest 024 incarnation continues to refine and polish this proven performer.

Delivering dependable performance across the widest possible wind range. A perfect blend of power and control.

Both Blade and BladePro have been developed on an identical platform. The PRO construction offers the ultimate experience while the Blade replicates the dynamic performance in a more accessible construction.

Both constructions utilize GRADIENT PANEL TECHNOLOGY to logically reduce weight, increase strength, and control stretch. Direct transmission of power. Increased longevity.

The Blade features quality materials including VX2, SpiderFibre, and eM4. The BladePro is crafted in CARBON FUSION.

Total Control. The Blade is the control-oriented wave sail for any conditions.

/ 5 BATTEN DESIGN

/ 100% X-PLY

/ DEVELOPED WITH SCOTT MCKERCHER AND PHILIP KOSTER

SIZES 3.0 / 3.3 / 3.5 / 3.7 / 4.0 / 4.2 / 4.5 / 4.7 / 5.0 / 5.3 / 5.5 / 5.7 / 6.2 / 6.7

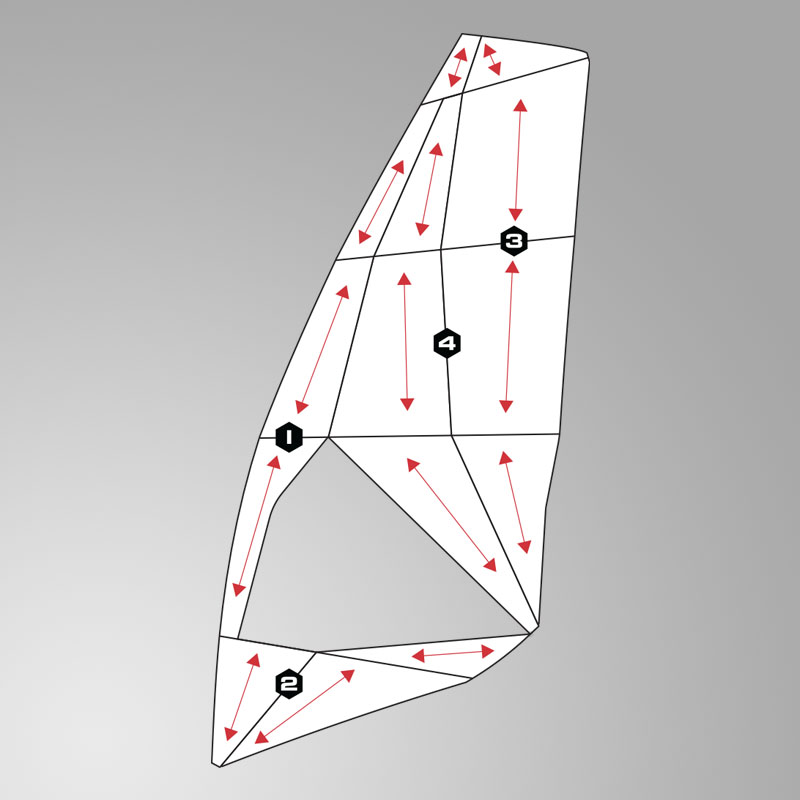

The Blade Pro uses the new GRADIENT PANEL TECHNOLOGY. Corners have overlapped panels which reduces the amount of patching. At the same time these overlapped areas extend into the body of the sail so it transitions the load much better, will be less stretch over time. It’s a more stable way of building sails.

Rather than a single curved luff panel, the Blade Pro uses separate panels that radiate out of the head and tack corners. This perfectly aligns the sail material with the direction of load. Previously the curved panel would have bias stretch in all the wrong places. Direct transmission of power. Increased longevity. Total Control.

In our quest to create a truly symmetrical sail we have developed the AERO BATTEN POCKET. Rather than add the batten pocket on one side of the sail, the panels of the sail are overlapped to create a channel for the batten. The tensioner is then loaded from both sides of the sail creating even tension across both sides of the foil.

The result is improved sail symmetry and reduced weight.

PRECISE. ALIVE. ELECTRIC

Our search for higher performance has brought us CarbonFusion, the next level in load-path sail construction.

Carbon Fusion sails are composed of 3 key components;

/ MATERIAL

/ FUSED SEAMS

/ LOAD PATH FRAME

The result of these 3 key components effectively turns the sail into a spring. Load it up, and release for explosive performance.

With the new GRADIENT PANEL TECHNOLOGY improvements are obvious. Lighter weight and better stability.

Using the new GRADIENT PANEL TECHNOLOGY. Corners have overlapped panels which reduces the amount of patching. At the same time these overlapped areas extend into the body of the sail so it transitions the load much better, will be less stretch over time. It’s a more stable way of building sails.

The GRADIENT PANEL TECHNOLOGY logically reduces weight, increases strength and controls stretch. Overall weight is reduced but the more significant improvement is the feel – quicker reacting and lighter feel.

Rather than a single curved luff panel, we use separate panels – split luff – that radiate out of the head and tack corners. This perfectly aligns the sail material with the direction of load.

Previously the curved panel would have bias stretch in all the wrong places. Direct transmission of power. Increased longevity.